Literatur

Additive Manufacturing

CFK Think composites

Zertifizierungen

- DIN EN 9100:2018 und DIN EN ISO 9001:2015

- Instandhaltungsbetrieb Teil 145, Referenznr. DE.145.0253

- Herstellungsbetrieb Teil 21 G, Referenznr. DE.21G.0048

- Herstellerqualifikation nach DIN 2303 Q2,Q4

Einkauf

Tanks

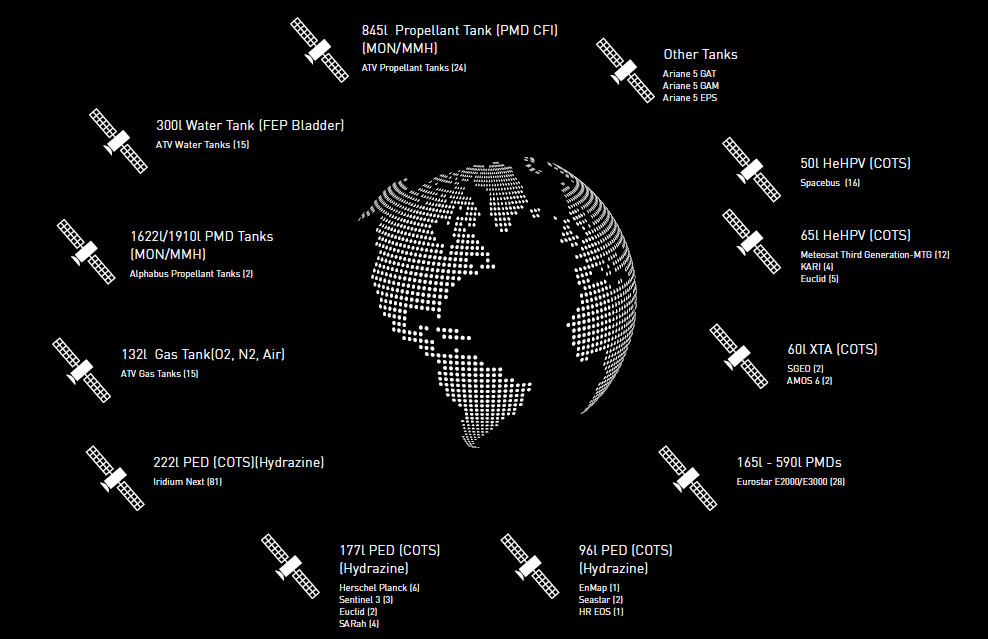

MT Aerospace’s Spacecraft Tank Centre runs a dedicated Design and Manufacturing facility for satellite propulsion tanks (chemical- & electric propulsion) at its site in Augsburg, Germany. The product portfolio includes:

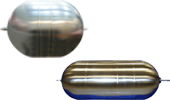

Monopropellant propulsion tanks (Positive Expulsion Device – PED) with EPDM-diaphragm (silica-free) and catalyst hydrazine and pressurant nitrogen or helium. Diaphragm tanks prevent propellant sloshing to a great extent and are capable of orienting the propellant even at high disturbance torques and accelerations. MT Aerospace does have in-house design & manufacturing capabilities for these tanks.

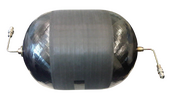

Bipropellant propulsion tanks (Surface Tension Tanks) fueled with monomethylhydrazin (MMH) and its oxidizer nitrogen tetroxide (NTO). In order to avoid stress corrosion defects in titanium propellant tanks, 1 or 3% of nitrogen oxide (NO) per weight by volume is added to the oxidizer NTO. This mixture is called MON1 or MON3 (MON = Mixed Oxides of Nitrogen) depending upon the percentage of NO used. MT Aerospace does not have the design authority for the Propellant Management Device (PMD), therefore, PMD-tanks are being manufactured “build-to-print” for all major satellite primes.

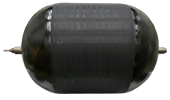

Electric Propulsion Tanks (EP) as well as high pressure vessels (HPVs). Electric propulsion tanks are mainly designed and build for xenon applications and the HPV for helium or nitrogen usage. Full design authority lies with MT Aerospace.

For all tanks, MT Aerospace strives to pursue for family concepts of the tanks in order to satisfy customer requirements. Furthermore, MT Aerospace manufactures all tanks on site Augsburg, controlling the entire supply chain such as liner welding, carbon fiber overwrapping with its own filament winding machines (COPV) and tank-testing equipment. With its own R&D budget, MT Aerospace develops the next generation of tanks further in areas such as demisable tanks and green propellant applications.

Under a current ESA project called “ViDA” – Verification of Diaphragm Analysis”, a sloshing simulation model for diaphragm tanks has been developed, enabling MT Aerospace analyzing sloshing behavior for pre-defined load cases and validate by experiment via mock-up testing.

Diaphragm Tanks

PMD Tanks

High Pressure Vessels (HPV)

High Pressure Vessels (HPV) Helium, Nitrogen & Xenon

High Pressure Vessels (HPV) for Electric Propulsion (EP) / Xenon Tank Assembly (XTA)

ATV Program (Restart Activities Required)

Tanks in Space